Underground Thermal Energy Storage

Underground Thermal Energy Storage: a greener, cheaper future

What do the National Museum ,Stoneheng, Machester's historic town and a large aprtment complex on the Thames have in common?

They are all looking at a greener, more cost-effective and efficient future. Despite their difference all four have had undergound thermal energy storage systemns (UTES) installed for heating and cooling. With energy savings of up to 50%, a reduction in carbon emissions of up to 60%, UTES systems are perfect where heating and cooling of 250kw and upwards are required - and they meet the current energy critiria required by Planning Authorities.

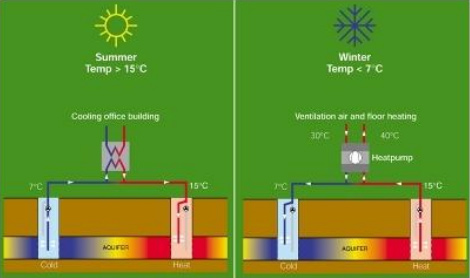

UTES is a cost effective, low energy, low risk and proven technology. It works on a known principle of storing excess summer heat energy for use in winter and winter cooling reserves for use in summer. Where a suitable aquifer exists the best value system in an open loop system, known as an ATES.

UTES specialists IFTech have been installing these systemns across Europe since 2006, designing and implementing over 1.000 UTES systems in the Netherlands alone. They are currently working on ten major UTES systems across the UK and one of the largest projects is the installation of an open loop reversible ATES system in London. They've partnered with Boode to ensure that only the most efficient and effective materials are used in the drlling and installation process.

The Riverlight scheme is a large residential project in London with a 2.9MW cooling and heating ATES system being installed for five mixed use buildings including 200 luxury apartments, affordable apartments and commercial space. The reversible system comprises 8 wells, 4 warm and 4 cold, 130 meters deep and delivering a planned peak groundwater flow rate of 50m3/hr per well.

Boode are supplying the PVC well casings as using the right casing is critical to ensure a trouble-free drilling process and achieve the appropriate flow rate. Conventionally, carbon steel casing is used at the 'conductor' stage but its weight can make access more difficult in the early stages of drilling and the quality of steel needed to achieve the required thickness can make it more expensive. Boode casings are comparetively light, easy to handle on-site and supplied threaded or with solvent weld connections. Corrosion free, and extruded slowly to achieve cylindrical perfection, they are approved bij KIWA, WRAS and the Secretary of State under Regulation 31.

Boode's 330mm OD x 292mm, 19,5mm wall thickness (heavy wall) PVC casing deals with the grouting and onward drilling phase without issue. Approval under Regulation 31 of the Water Supply (Water Quality Regulations) means that, should the wells ever be required for potable water abstraction they are already compliant. The cylindrical perfection of Boode's PVC casings simplifies the drilling & installation process, one of the reasons why IFTech use Boode PVC casings, and screens where required, in the majority of their projects, both in the UK & Europe.

![]()

Click here and download this article as a PDF.